More Friction Material Manufacturers

Applications

Friction materials are engineered for critical applications where controlled resistance is required to slow, stop, or hold motion. The most common uses for friction materials include automotive brake systems, clutch assemblies, industrial braking equipment, gear tooth systems, and machinery that demands reliable stopping or deceleration. Components such as friction pads, brake linings, clutch facings, and disc brake pads are meticulously manufactured from specialized friction compounds to meet the diverse needs of modern industries.

Industries that rely heavily on friction materials are vast and varied. These include:

- Automotive: Used extensively in passenger vehicles, trucks, buses, motorcycles, and performance cars for disc brakes, drum brakes, and clutches.

- Construction: Heavy machinery such as excavators, loaders, bulldozers, and cranes depend on industrial brake pads and clutch systems for safe operation.

- Forestry and Agriculture: Tractors, harvesters, and lumber equipment utilize friction linings and clutch discs to ensure smooth, controlled movement and safe stopping.

- Oil and Gas: Friction materials help operate winches, hoists, drilling rigs, and other heavy-duty equipment requiring robust braking capacity.

- Mining: Large vehicles and processing equipment use heavy-duty friction blocks, pads, and bands designed for extreme environments.

- Rail and Transit: Trains, trams, and metros utilize specialized brake shoes, pads, and blocks for high-reliability stopping power.

- Marine: Winch systems, anchor controls, and propulsion systems utilize marine-specific friction materials resistant to saltwater corrosion.

Are you searching for the best friction material for your specific project or application? Compare leading friction material types to see which is best suited for your operational environment, whether it’s high-heat, high-load, or frequent stop-and-go conditions.

Braking Systems

At the heart of every effective braking system are high-performance friction materials. Whether in automotive brakes, heavy machinery, or industrial automation, these materials convert kinetic energy into heat, enabling rapid deceleration or complete stops. When a brake is engaged, the friction material makes contact with a moving disc, drum, or wheel, generating resistance and dissipating energy. The safety, reliability, and performance of vehicles and equipment depend on the quality and suitability of the chosen friction material.

Beyond basic stopping power, advanced friction materials are engineered for low noise, minimal dust production, excellent wear resistance, and consistent performance under extreme temperatures. Applications range from regenerative braking systems in electric vehicles to high-load braking in mining trucks and high-speed rail systems.

The History of Friction Materials

Friction, a fundamental force of nature, has been harnessed and studied for thousands of years. Early humans relied on the heat generated by friction to spark fire, using simple tools and techniques to survive and innovate.

Ancient Greek and Roman scholars, such as Pliny the Elder, Aristotle, and Vitruvius, were among the first to document their observations and methods for manipulating friction. Their works provided foundational knowledge for future generations and inspired centuries of innovation in the management of frictional forces.

Leonardo da Vinci, in 1493, was the first to record the classic laws of sliding friction in his detailed notebooks. These laws, though not published during his lifetime, were rediscovered by Guillaume Amontons in 1699, who formalized them into Amonton’s three laws of dry friction. These breakthroughs marked the beginning of scientific study into static, kinetic, and rolling friction, which remain central to the field of tribology—the science of friction, lubrication, and wear.

Subsequent milestones included John Theophilus Desaguliers’ discovery in 1734 that friction could create enough force to tear adhered surfaces apart, and Arthur Jules Martin’s 1833 clarification of the difference between sliding and rolling friction. These foundational laws and discoveries laid the groundwork for the modern friction materials industry.

The modern era of friction materials began in 1888, when Bertha Benz, during one of the first long-distance automotive journeys, invented the concept of brake pads, using leather as a friction material to improve braking safety. By the early 20th century, asbestos became the dominant material due to its durability, heat resistance, and affordability. However, by 1989, health risks associated with asbestos exposure—such as cancer and lung disease—prompted a global shift toward safer alternatives.

Today, synthetic aramid fibers (like Kevlar), advanced ceramics, semi-metallic compounds, and organic friction materials have replaced asbestos. Each offers unique benefits for specific applications, from high-heat resistance and low dust to superior noise reduction and environmental safety. As regulatory standards continue to evolve, manufacturers are investing in research and development to create friction materials that are safer, more durable, and more sustainable than ever before.

With continuous innovation, modern friction materials deliver reduced noise, faster stopping times, longer service intervals, and compatibility with advanced vehicle systems such as ABS (Anti-lock Braking Systems) and ESC (Electronic Stability Control). The future promises even greater performance as new composites, nanomaterials, and eco-friendly alternatives are developed to meet the demands of next-generation vehicles and equipment.

Design

Materials

The design of friction materials is a sophisticated process that balances performance, durability, safety, and cost. Since friction inherently generates heat, manufacturers prioritize heat-resistant compounds for high-performance applications. Historically, asbestos fibers were popular for their resilience and thermal stability. With heightened awareness of health and environmental risks, the industry has transitioned to alternatives such as advanced ceramics, aramid fibers, and proprietary organic blends.

Ceramic friction materials are renowned for their exceptional heat tolerance, fade resistance, low dust, and quiet operation. They are ideal for high-performance automotive and motorsports applications as well as heavy-duty industrial brakes. Semi-metallic friction materials—blends of metal fibers (brass, copper, steel wool) and resins—provide excellent durability and heat dissipation, making them common in commercial vehicles, trucks, and buses.

Organic friction materials (using natural fibers, resins, and fillers) are favored for applications requiring low noise and minimal environmental impact. Newer “low-metallic” and “non-asbestos organic” (NAO) formulas combine the best traits of each material type, tailored for specific performance requirements.

Are you evaluating friction material options for a specific use case? Ask a friction materials supplier about the advantages of ceramic vs. semi-metallic vs. organic compounds for your industry or equipment.

Considerations and Customization

Choosing the right friction material depends on the specific type of friction involved and the operational environment. The three main types of friction are:

- Static friction: The force that must be overcome to initiate motion between two stationary objects. Applications include holding mechanisms, parking brakes, and load-holding clutches.

- Kinetic (dynamic) friction: The resistance encountered when two surfaces slide against one another. This type is most relevant in disc brakes, drum brakes, and clutch engagement systems.

- Rolling friction: Occurs when objects such as wheels or ball bearings roll over a surface. It is a critical factor in tire design, conveyor rollers, and precision machinery.

Key factors influencing the selection of friction materials include:

- Required coefficient of friction (static and dynamic)

- Operating temperature range and heat dissipation needs

- Wear and abrasion resistance

- Noisiness and vibration control

- Frequency and intensity of use

- Compatibility with other system components (e.g., rotors, drums)

- Budget and lifecycle cost

- Regulatory and environmental requirements (e.g., copper-free, asbestos-free)

Friction materials can be custom-engineered for specific applications by adjusting the blend of fibers, fillers, binders, and surface treatments. Textured or grooved surfaces are common in brake pads and clutch facings to boost friction and facilitate heat dissipation, while smoother finishes are used where low friction and minimal energy loss are desired. Rubber or elastomeric additives may be introduced to further improve grip and reduce noise.

Looking for friction material customization options? Contact a friction material manufacturer to discuss your requirements for performance, longevity, and compliance with industry standards.

Features and Benefits

Friction materials are vital to the safe and efficient operation of vehicles and machinery across a multitude of sectors. Here are some standout features and benefits:

- Energy conversion: Converts kinetic energy into heat, allowing for controlled deceleration and stopping.

- High temperature stability: Maintains performance under repeated heavy braking or high-speed operation.

- Consistent friction coefficient: Ensures predictable stopping distances and reliable system response.

- Low noise and vibration: Advanced compounds and surface designs minimize squealing, grinding, and rattling.

- Wear resistance: Optimized for long service life, reducing downtime and maintenance costs.

- Environmental safety: Modern materials are manufactured to be copper-free, asbestos-free, and compliant with the latest regulatory standards.

- Customization: Tailored friction characteristics for specialized applications, from high-performance racing to heavy-duty industrial use.

In hybrid and electric vehicles, friction materials play a dual role. Not only do they provide traditional braking, but they also enable regenerative braking systems—capturing kinetic energy and converting it into electrical energy to recharge batteries, enhancing overall efficiency and sustainability.

Types of Friction Materials and Components

A wide variety of products are manufactured using friction materials, each designed for specific roles in automotive, industrial, and specialty equipment. Common examples include:

- Brake blocks: Rigid friction materials that press against wheel rims to slow or stop motion, widely used on bicycles and rail equipment.

- Brake shoes: Metal plates that carry friction linings, forming a key part of drum brake systems in autos and heavy machines.

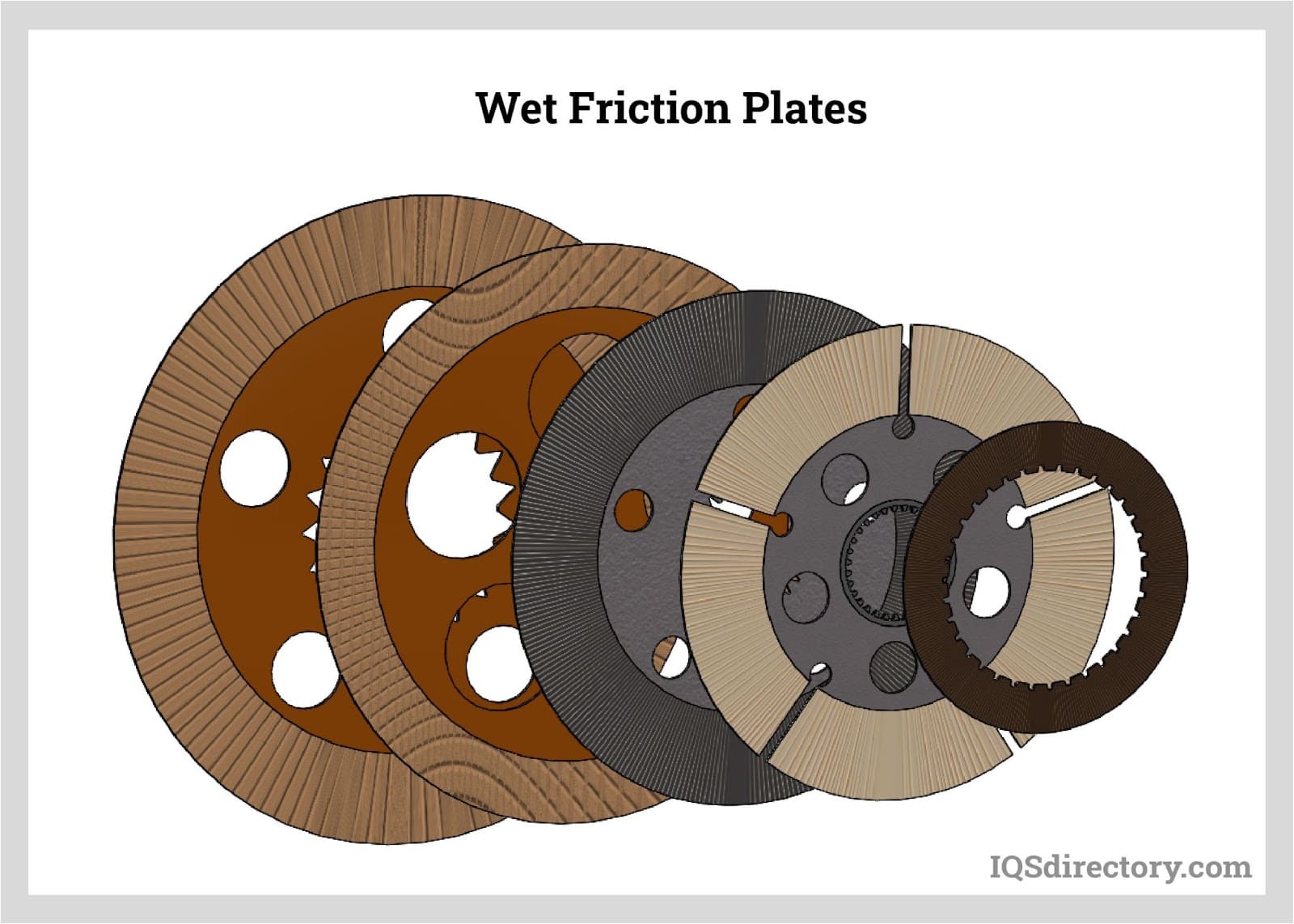

- Friction discs (friction plates): Metal or composite discs bonded with friction material, critical in automotive and industrial brake and clutch assemblies.

- Clutch discs (friction clutch discs): Transfer engine power to the transmission in vehicles, allowing for smooth gear changes and power management.

- Clutch facings: Specialized friction materials that ensure stable, quiet, and efficient torque transfer in clutches.

- Brake linings: Heat-resistant materials bonded to brake shoes, designed to withstand high temperatures without igniting or degrading.

- Brake pads (brake bands): Metal plates with bonded friction surfaces (brake linings), available in drum and disc configurations for diverse braking systems.

Specialty components include friction rolls, bands, facings, segments, and rings for use in power transmission, elevators, cranes, wind turbines, and off-highway vehicles.

Wondering which friction component is right for your system? Explore our friction material product selection guide to compare types, advantages, and best-fit applications.

Proper Care and Maintenance for Friction Materials

Due to their role in safety-critical systems, friction materials are subject to frequent wear and require regular inspection and maintenance. While their longevity varies based on application and usage intensity, proactive care can maximize performance and prevent costly failures.

Signs of Wear: The most common indicator of brake or clutch material wear is audible squealing or squeaking during operation. If you notice persistent noise or reduced braking effectiveness, inspect the relevant components for thinning, glazing, or contamination.

For braking systems, grinding noises indicate that friction material is worn through, potentially causing damage to metal rotors or drums. Prompt replacement is essential to avoid more expensive repairs and maintain safe operation.

Another common issue is contamination from oil or brake fluid leaks. “Brake chatter,” characterized by vibrating noises, often signals the presence of contaminants. If detected, repair the source of the leak and replace both pads or linings simultaneously to maintain even wear and consistent braking performance.

Regularly scheduled inspections, proper bedding-in procedures for new materials, and adherence to manufacturer recommendations are key to extending the life of your friction materials. For heavy-duty or high-performance applications, consult your supplier for specific maintenance intervals and best practices.

Need help with friction material care or troubleshooting? Contact our technical support team for expert advice on maintenance, replacement schedules, and system optimization.

Industry Standards and Compliance

Friction materials are governed by stringent industry standards to ensure safety, performance, and environmental responsibility. In the United States, the Environmental Protection Agency (EPA) sets regulations concerning hazardous substances in brake and clutch materials, including bans on asbestos and restrictions on copper and heavy metals.

For products sold internationally, compliance with RoHS (Restriction of Hazardous Substances) is essential, especially for shipments to the European Union. The Friction Materials Standards Institute (FMSI) provides standardized part numbering and technical guidelines, while SAE International offers performance testing protocols and material specifications.

Additional industry-specific certifications may apply to automotive, aerospace, transit, or industrial equipment, so it’s important to verify that your chosen supplier meets all relevant requirements for your region and application.

Curious about regulatory compliance for your friction materials?

Request documentation and certification from your supplier to ensure peace of mind and seamless regulatory inspections.

Things to Consider When Selecting Friction Materials

Choosing the right friction material or component is a strategic decision that impacts the safety, efficiency, and cost-effectiveness of your operation. Here’s how to approach the selection process:

- Define your requirements: List your application details—performance needs, operating environment, required service life, compliance standards, and budget.

- Research suppliers: Use our directory of top friction material manufacturers to compare capabilities, certifications, and customer reviews.

- Request product samples and technical data: Evaluate materials for coefficient of friction, thermal stability, noise characteristics, and environmental compliance. Ask for case studies or testimonials related to your application.

- Engage with technical experts: Consult supplier engineers or technical support teams to discuss custom formulations, design modifications, or high-performance options.

- Compare proposals and select partners: After gathering information and quotes, weigh your options based on total value—performance, price, service, and long-term support.

Are you ready to upgrade your friction materials or need help specifying the right product? Contact multiple manufacturers for quotes and technical advice, or request a friction material consultation to ensure you’re making an informed, future-ready investment.

Frequently Asked Questions About Friction Materials

- What’s the difference between organic, semi-metallic, and ceramic friction materials? Organic materials are made from natural fibers and resins, offering quiet operation and minimal rotor wear. Semi-metallics contain metal fibers for durability and heat resistance, but can be noisier. Ceramics provide high-temperature stability, low dust, and quiet performance, popular in both OE and aftermarket automotive applications.

- How do I know when to replace brake pads or clutch facings? Listen for unusual noises (squealing, grinding), feel for reduced braking power or clutch engagement, and visually inspect for thin or uneven wear. Always follow maintenance guidelines for your specific vehicle or machine.

- Are modern friction materials environmentally friendly? Yes. Recent regulations have phased out asbestos and restricted the use of heavy metals and copper. Most new formulations are compliant with EPA, RoHS, and state-specific laws (e.g., Washington and California copper-free initiatives).

- Can friction materials be customized for unique applications? Absolutely. Manufacturers can tailor formulations for specific friction coefficients, wear rates, noise levels, and thermal properties. Custom shapes, sizes, and surface treatments are also available.

- What factors influence the lifespan of friction materials? Application type, frequency of use, operating temperature, load, and environmental conditions all play a role. Using the right material for the job and following recommended maintenance schedules are key to maximizing service life.

Have more questions about friction materials? Ask our team or browse our knowledge base for expert answers on all aspects of friction materials selection, use, and care.

Find the Right Friction Material Supplier

Partnering with a reputable supplier is essential for ensuring product quality, safety, and value. Explore our curated list of industry-leading friction material manufacturers, each offering unique strengths in R&D, custom engineering, volume production, and technical support. Before contacting suppliers, define your needs—performance targets, budget, standards, and delivery requirements—then reach out to 3-4 candidates for proposals. Ask detailed questions about experience, testing protocols, warranties, and post-sale support. After comparing responses, select the partner who best aligns with your goals and values.

Ready to take the next step? Browse our full friction material manufacturer directory or request a quote for your next project to get started with reliable, high-performance solutions tailored to your needs.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services