The incorporation of clutch facings allows for smoother and more consistent clutch engagement and disengagement which results in a smoother ride and has the potential to reduce output costs per mile. Read More…

You only need to know one name for your friction material needs: Cook Bonding & Manufacturing. We have been working hard for over 3 decades and specialize in the manufacture of high quality friction materials, gear tooth facings, press blocks, and more.

As the originators of sintered metallic friction materials, GMP Friction Products develops unique clutch plate and brake pad solutions tailored to our customers` needs. We have a dedicated staff for research and development, devoted to engineering materials that provide the optimum blend of durability and effectiveness. We serve the agricultural, vehicle, aerospace, and other specialty markets.

As a complete friction materials company you can send us your custom fabrication, bonding, relining, riveting, brake lining or clutch assembly questions and we will provide you with fast & competitive quotes. At Phoenix Friction we understand the importance of finding reliable, timely & cost-effective solutions for your friction material problems and that is why strive for 100% customer...

More Clutch Facing Manufacturers

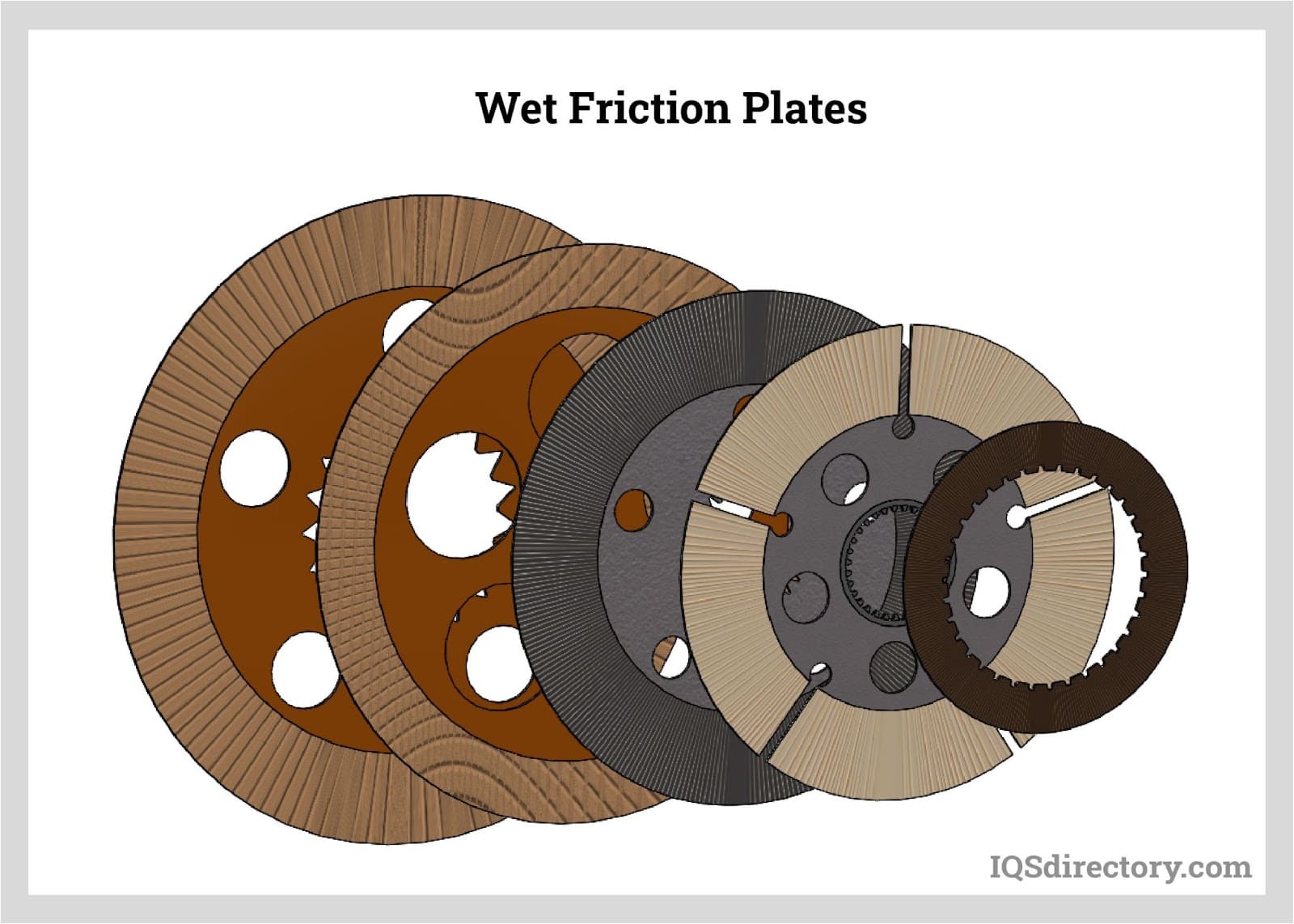

Clutch facings can be manufactured from a range of materials depending on application and some of the most common are asbestos, woven fibers such as Kevlar or aramid and ceramic materials. As with disc brake pads and other clutch materials, the materials used in clutch facings need to be durable. The process of engaging and disengaging drive shafts involves the transfer of kinetic energy into heat energy; therefore clutch facings need to be able to endure the tension of the process as well as the high temperatures which will be reached. Clutch facings are used in marine engines, heavy duty truck and lightweight vehicle engines as well as power presses, friction blocks and a number of industrial applications. The smooth and stable performance of many engines can be attributed to the existence of a quality clutch facing.

There are a number of reasons for the use of clutch facings. A major benefit to using a lining or facing is that it prevents metal-to-metal contact within the clutch set, resulting in less wear and tear on the clutch components. Clutch facings tend to have mid-level coefficients of friction, and are responsible for removing most of the clutch vibrations from the engine. If there was no clutch facing, the metal parts would wear out a lot faster, and the noise and vibrations from the clutch would be higher. They also aid in allowing engines to achieve high speeds without damaging the components.

When the clutch is engaged, power can be transferred to the transmission and drive-wheels from the engine. The clutch facings ensures the gears do not grind against each other during this process, and provide elasticity and support. The facings will inevitably wear down as a result of the pressure and often extreme conditions within the engine, especially if consistently run at high speeds. Clutch linings therefore need to be periodically checked and replaced if necessary to ensure that protective elements are still in tact and that optimum performance is being achieved.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services