Clutch systems that utilize these materials are made up of several components such as clutch facing, pressure plates, clutch discs, and flywheels. The many different mechanical parts require many different materials. Likewise, the myriad of applications for clutches necessitates variable construction. Read More…

You only need to know one name for your friction material needs: Cook Bonding & Manufacturing. We have been working hard for over 3 decades and specialize in the manufacture of high quality friction materials, gear tooth facings, press blocks, and more.

ProTec Friction Group is a producer of friction components and forms. By combining our manufacturing expertise with our supply chain knowledge, we are able to bring friction solutions to our customers.

Cleveland Oak's friction material products division designs & manufactures friction products such as brake shoes, clutch facings, bands, disc brake pad products plus clutch pads. We keep metric & standard molded, sheet & woven friction materials in stock & perform friction materials bonding and riveting. In business since 1916, our high quality friction materials are economically priced as well.

For more than 60 years Clutch Engineering has been a distributor in industrial power transmissions. Our specialties are in brakes & clutches, flexible couplings, universal joints & driveshafts, and friction materials. With our expert team and determination, we strive to exceed the consumer's expectations.

The Friction Group of Miba HydraMechanica designs and manufactures friction materials and brake friction materials for wet and dry applications. We serve various industries, including automotive and agricultural. Visit our website today for more information on our friction materials.

More Clutch Material Manufacturers

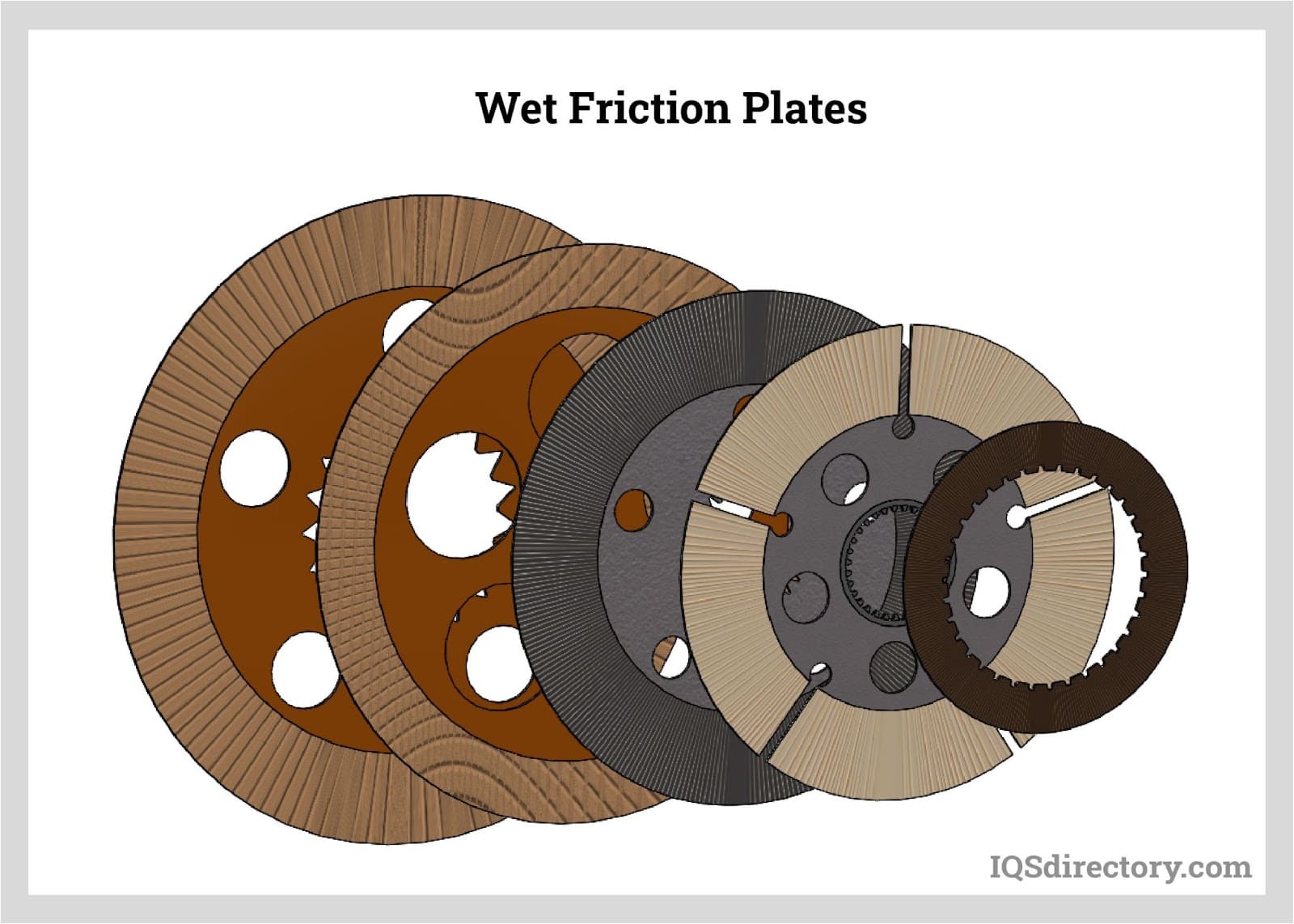

Clutch materials are used in automotive, railway, transit coach, motorcycle, construction machinery and agricultural industries to help control speed and gear shifting in vehicles ranging from tractors to race cars. No matter the size or specific part, there are general guidelines for clutch materials. These materials must be strong and able to resist wear effects as might be accrued from scoring, galling and ablation. As shifting gears generates heat as a byproduct, these materials must account for thermal expansion and remain constant at a range of temperatures, have high heat capacity, good thermal properties and conductivity. These systems inherently deal with a great deal of pressure making the ability to withstand high contact pressures essential to their functionality.

Clutch apparatus may be exposed to the environment and must be able to endure moisture, dust and other environmental factors while continuing to provide consistent clutch engagement and disengagement. Many, but not all, components are subject to frequent friction. These particular components must exhibit all of the above qualities while also maintaining a high coefficient of friction, which is the ratio of the force of friction between two bodies in contact with one another. These friction materials are often rough or textured to provide added friction and increase efficiency.

In general, the compression of a clutch pedal or lever causes several springs connected to a pressure plate to compress as well. This pulls the plate, and connected clutch disc, away from the flywheel which is bolted to the engines crankshaft. The disconnection stops the rotation of the clutch disc which intern disconnects the central hub of the disc from the input shaft. The driver may then shift gears or coast. After shifting, the pedal is released and the clutch disc reengages the flywheel. The clutch system works to ensure consistent clutch engagement and disengagement. Among the high stress but low friction components such as the pressure plate, steel, cast iron, aluminum and ceramics are common. While asbestos was once the most popular choice for elements encountering large amounts of friction, health hazards have lead clutch manufacturers to find alternatives.

Ceramic, copper, steel, iron, mineral, cellulose, aramid, chopped glass, rubber and brass fivers are all used in the creation of composite materials used in clutches. These amalgamations are useful in that they retain the qualities, friction resistance and strength, of any and all powders and fibers used in their formation. These clutch materials are often attached via rivets or strong adhesives to metal bases. Field experience, as well as chemical and material engineering, allows constant advancements in clutch material design. These advancements result in reduced maintenance and operating costs, longer wear life, better functionality and overall consumer satisfaction.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services