Rather than find the numerous parts individually, several parts can be purchased as a single package deal. Read More…

You only need to know one name for your friction material needs: Cook Bonding & Manufacturing. We have been working hard for over 3 decades and specialize in the manufacture of high quality friction materials, gear tooth facings, press blocks, and more.

As the originators of sintered metallic friction materials, GMP Friction Products develops unique clutch plate and brake pad solutions tailored to our customers` needs. We have a dedicated staff for research and development, devoted to engineering materials that provide the optimum blend of durability and effectiveness. We serve the agricultural, vehicle, aerospace, and other specialty markets.

As a complete friction materials company you can send us your custom fabrication, bonding, relining, riveting, brake lining or clutch assembly questions and we will provide you with fast & competitive quotes. At Phoenix Friction we understand the importance of finding reliable, timely & cost-effective solutions for your friction material problems and that is why strive for 100% customer...

More Clutch Sets Manufacturers

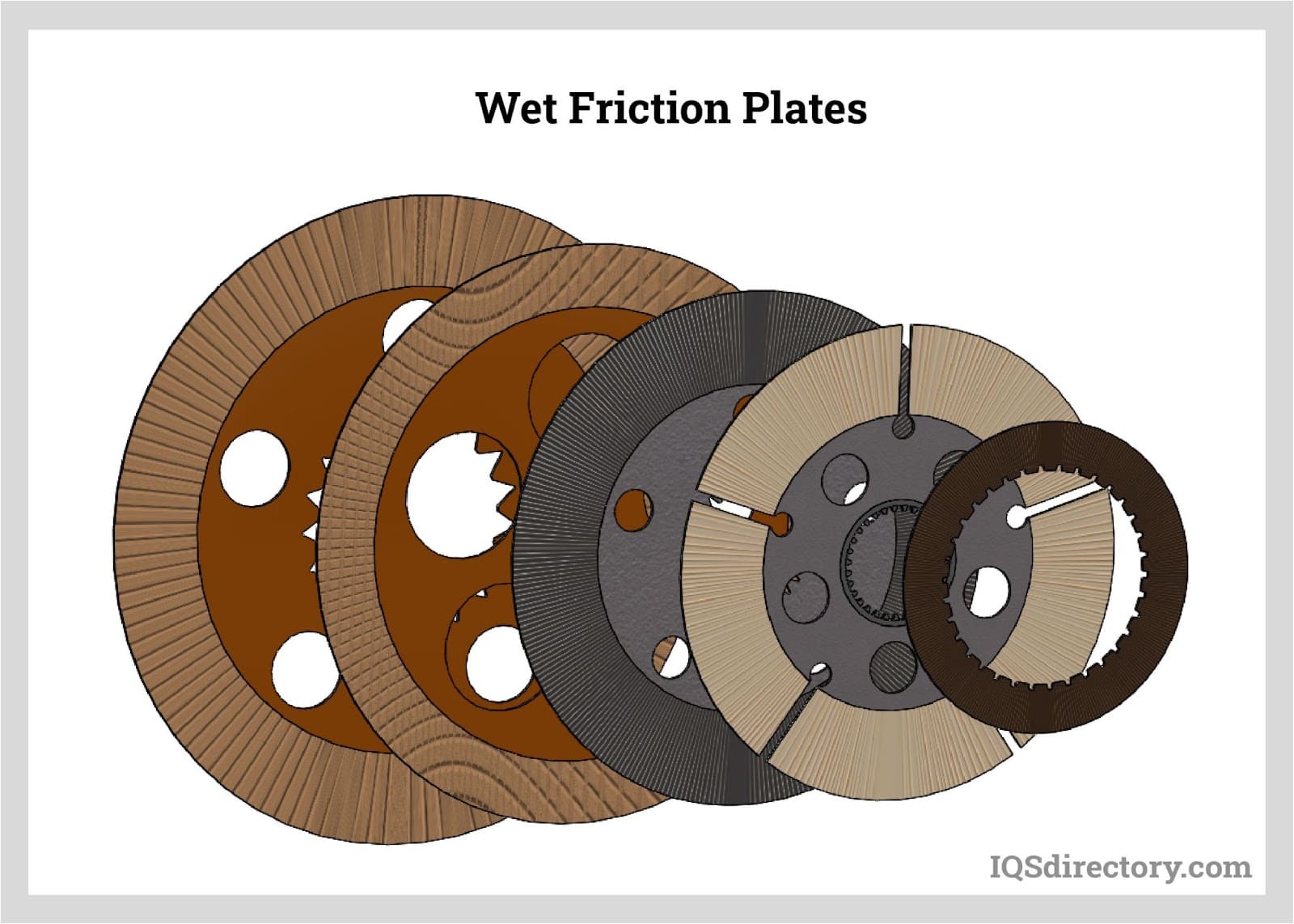

Motorcycles, cars, agricultural and industrial equipment, trucks, transit coaches and even some diesel locomotives utilize clutches. This broad array of uses necessitates a tremendous variety in clutch design, operation and production. For that reason there is an expansive market for clutch sets. Some kits are designed for the specific model and year of a vehicle while others offer more general applications.

While the manufacturers provide the initial clutch, consumers are responsible for clutch replacement. In addition to replacement kits, performance enhancing clutch sets are also available and widely used, especially in competitive cars. These kits are designed to improve the speed of shifting as well as the vehicles capacity to handle increased horsepower and torque. Torque rating, power, rotational speed and maximum pressure allowances are important considerations when selecting the proper clutch for a given application.

In general, the compression of a clutch pedal or lever causes several springs connected to a pressure plate to compress as well. This pulls the plate, and connected clutch disc, away from the flywheel which is bolted to the engines crankshaft. The disconnection stops the rotation of the clutch disc which intern disconnects the central hub of the disc from the input shaft. The driver may then shift gears or coast. After shifting, the pedal is released and the clutch disc reengages the flywheel. The clutch system works to ensure consistent clutch engagement and disengagement. As the friction from this process generates a great deal of heat and pressure, materials for each clutch component are carefully chosen.

Metallic and ceramic composites are among the most common selections for those parts which incur the greatest wear, while steel and other durable metals are used where friction materials are less essential. When selecting a clutch set it is important to consider the materials used to produce each component. It is also important to be clear as to what constitutes a kit as some are more inclusive than others. Some sets provide the clutch, or lever, and pressure plate while others include pilot bearings, throw-out bearings, discs, and alignment tools as well.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services